Aggregate is the granulate bulk material mixed with cement and water as framework or filling material while making concrete, such as sand and stone. They take up 75% of the total volume of concrete, and are divided into coarse aggregate(pebble, clastic rock, waste residue, etc) and fine aggregate(sand and coal ash, etc)

Aggregate is the main material for heavy construction program, such as: railway and expressway construction. And the rapid development of infrastructure(railway, highway, bridge and hydroelectric station) has a large demand on fine aggregate. There are two type of aggregate processing system: natural aggregate processing system and artificial aggregate processing system, and are applied according to the condition of material source. We will choose the former one when the natural aggregates are plentiful and of good grading, then the later one while there is a material deficit or large grade differences or large material discard.

Ordinarily, we can purchase aggregate from quarry of small size with small demand during infrastructure construction. However, most constructions of railway, high way, bridge and hydroelectric station have a large need for high quality concrete, which demands highly qualified aggregate but are restricted by narrow construction site and limited working period. Consequently, it will be the fundamental purpose of sand making machinery manufacturer to develop equipment with modern technical standard and excellent dynamic economical indicator to ensure the quality of artificial aggregate and make it possible to achieve running output balance during construction period.

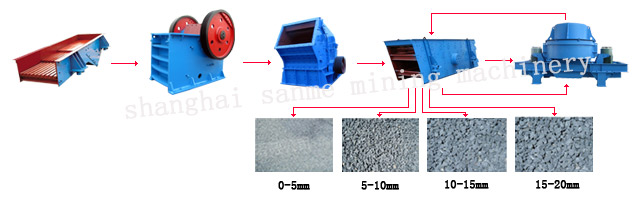

Our company provide our customers with the whole series of stone production line as well as comprehensive technical support. The production line mainly consists of feeder, jaw crusher, impact crusher, viberating screen, vertical shaft impact crusher and belt conveyor, coordinating with belt conveyor to form a complete stone production line.

Application Scope:

This production line can be used for processing hard limestone, granite, basalt, pebble, matellurgical slag, and is applied in hydroelectric project, construction material, express way and city construction industries. Different process requirements can be achieved through changing the model according to the needs of the customers.

Production flow:

Feeded by viberating feeder, the mined ore is primarily crushed in jaw crusher and then shaped in hydraulic cone crusher after meeting the size requirements, and finally recrushed in vertical shaft impact crusher. The end product is screened and selected by viberating screen, and its particle size is determined by the model of crusher and screen.

Performance Introduction:

1.high automation

2.High capability, high productivity efficiency, low operation cost and high profit.

3.Adjustable discharge particle size, high crushing ratio and low energy consumption.

4.uniformed Product size and excellent shape, which meets the national standard for express way aggregate.

Per: Iron ore Dressing

Next: [Solutions]